Tiger

Capacity M2-M27 (M33)

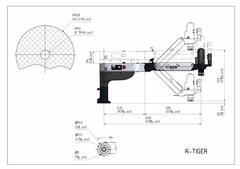

The machine itself consists of a radial arm joint to a tilting arm balanced by means of a pneumatic spring. The head member and the electric motor find themselves at the end of the tilting arm and is adapt to always move at right angle with respect to its working area.

Through the base (1) and by means of three M8 (120º) screws the machine can be fixed to a table or workbench. Such attachment can also be obtained by means of a simple clamp.

The speed is regulated by means a variator board located in the “electronic box casing”. The turning motor speed and the optional automatic lubrication and depth control are adjustable by means of the buttons being located over the “radial arm”. The speed can be thus adapted to every thread type.

Equipped with a single phase (220V or 110V) HIGH FREQUENCY MOTOR, is able to adapt the modular system consisting in a series of 7 quick-change modules (reducers). As a result of this output speeds are available thus allowing to adapt the tap speed to every type of thread.

| Description | Head Orientation | Speed (RPM) | Capacity (Metric) | Max. Torque (NM) | Arm Reach (MM) | Arm Height (MM) | Load (KW) |

| Tiger | Vertical | 90-1050 | M2-M27 | 150 | 1020 | 535 | 1.5 |

| Tiger-VH | Vertical & Horizontal | 90-1050 | M2-M27 | 150 | 1020 | 535 | 1.5 |

Lifter

We can increase the working area in 130 mm in order to work on different height levels

Electric motor

High Frequency Electric motor. Power 0,55 Kw. Single phase (220V or 110). Motor supply voltage: 200-240 V. 50/60 Hz. Less speed: 90 rpm – Highest speed: 2.100 rpm

VH (Vertical-Horizontal)

The ROSCAMAT TIGER –VH- (Vertical & Horizontal, 4×90º) includes an easily-handled articulated head assembly that allows the motor to be positioned in four 90° positions and tap in horizontal and vertical direction.

Working area

Roscamat tiger Radius: 1020 mm / High: 535 (660) mm

Roscamat tiger VH Radius: 1160 mm / High: 535 (660) mm

Modular System

The modular system provides for a new concept in the use of articulated tapping arm machines. Driven from a single motor, seven different speed modules are available with their relevant power torques. The seven quick-change speed modules provide the speed and torque for each threading type, from M2 to M27 (M33) threads.

Module | Max. Speed (rpm) | Max. Torque (Nm) | Coupling diameter | Max. Thread Aluminium Cast Irons | Max Thread Steel . |

90 | 90 | 150 | Ø 31 | M30 – 1 /1/8” | M27 – 1 “ |

170 | 170 | 79 | Ø 31 | M24 – 7/8” | M20 – ¾” |

300 | 300 | 44 | Ø 19 | M16 – 9/16” | M16 – 9/16” |

550 | 550 | 24 | Ø 19 | M14 – ½” | M12 – 7/16” |

750 | 750 | 17 | Ø 19 | M12 – 7/16” | M10 – 3/8” |

1050 | 1050 | 12.5 | Ø 19 | M8 – 5/16” | M8 – 5/16” |

2100 | 2100 | 6 | Con B-16 | To drill up to Ø 8 Aluminium, brass, etc. | |